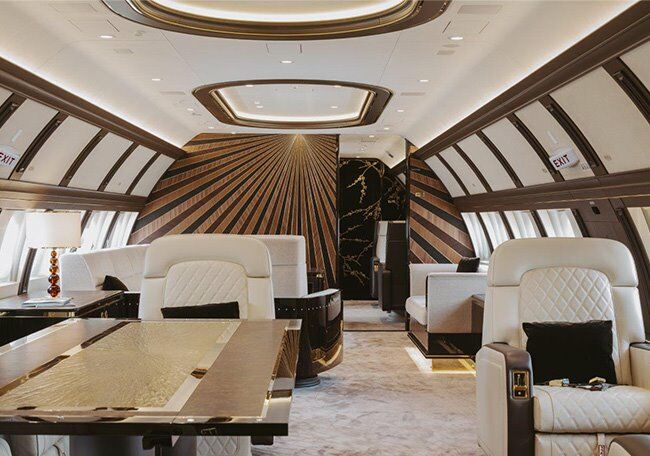

Creating Bespoke Design Solutions – the Story of a Marquetry

Beautiful craftsmanship and exquisite attention to detail are the hallmarks of any Jet Aviation crafted interior. Our recent ACJ319neo redelivery was no different, with a number of incredibly complex features hand-made in house.

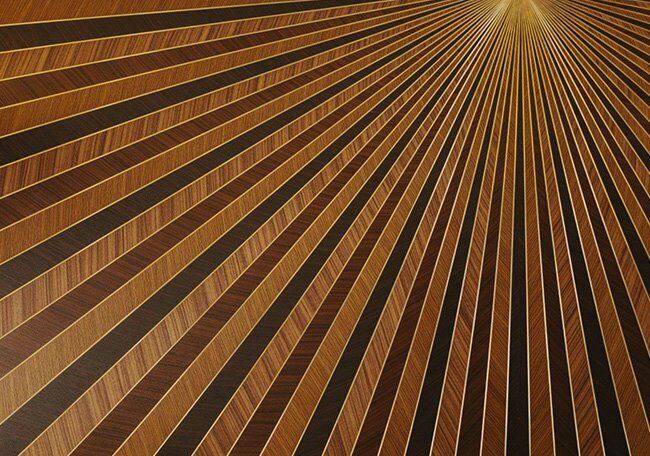

One of these was the bulkhead marquetry, with a detailed ‘sunburst’ design crafted from over 180 ‘rays’ composed of four different veneers (two light and two dark) separated with brass inlays of 3mm. Each piece was individually placed and manipulated by hand to ensure a seamless finish. It was a challenging, but ultimately very rewarding process, and is testament to our team’s commitment to meeting our customers’ expectations with fine craftsmanship and ingenuity.

The challenge came when the ACJ319neo customer asked us to review the design of his main bulkhead. Since the beginning of the project, the main lounge bulkhead design had been in discussion, with initial plans to use an embroidered fabric. Last summer however, the team was approached to propose another design crafted from veneer and plated decorative frame or inlays.

After further brainstorming and close cooperation with all departments, from Engineering to Installation, Interior Design, SCM and Production, the teams defined the best build-up considering many factors including the weight, technical aspects and design intent, ensuring each step of the manufacturing process was defined and closely controlled.

The teams dealt with multiple technical challenges along the way, but the final design expectations were met.

“We selected a strong team of experts with the right skills to make this project a success.”

“We selected a strong team of experts with the right skills to make this project a success,” says Production Project Manager Thomas Gensbittel. Once the panels were produced and pre-fitted, the veneer and varnish applied, the team started to prepare for the inlay’s installation. Each single inlay had to be adjusted manually to end at the top meeting point, with more than 60 inlays (180 in total on both bulkheads) prepared and glued manually into the panels.

“After several hours of hard and high precision work, the team achieved the decors in a short timeframe,” continues Thomas. “The challenge was completed for Production and handed over to Installation who did a great job in exchanging those decors in quick time! This collaboration, hard work and passion for the aircraft and our customer made it all happen”.??

“I want to address a big thanks to the full Thunderbird Team and a specific “high five” to our Production team (Eddy, Clément, Noory, Paul, Thilbaud, Materne, Sébastien, Morgan, Manu, Patrick) and to the Install team (Sebastien L, Sacha T, Cedric M),” he shares. “Such collaboration and accomplishment are what make our job exceptional!”